Taraxacum kok-saghyz

Taraxacum kok-saghyz, often abbreviated as TKS and commonly referred to as the Kazakh dandelion, rubber root, or Russian dandelion,[1][2] is a species of dandelion native to Kazakhstan, Kyrgyzstan and Uzbekistan, notable for its production of high-quality rubber.[3] T. kok-saghyz was discovered in Kazakhstan in 1932 by Soviet scientists seeking a domestic source of rubber.[2][4]

| Taraxacum kok-saghyz | |

|---|---|

| |

| The Russian dandelion | |

| Scientific classification | |

| Kingdom: | Plantae |

| Clade: | Tracheophytes |

| Clade: | Angiosperms |

| Clade: | Eudicots |

| Clade: | Asterids |

| Order: | Asterales |

| Family: | Asteraceae |

| Genus: | Taraxacum |

| Species: | T. kok-saghyz |

| Binomial name | |

| Taraxacum kok-saghyz L.E.Rodin | |

Etymology

Kok-saghyz is derived from the Kazakh kök-sağız (көк-сағыз), with kök meaning root and saghyz meaning rubber or gum. Its latex was traditionally used as a kind of chewing gum.[5]

Biology

Plant description

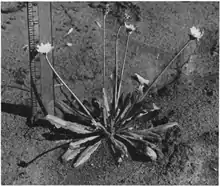

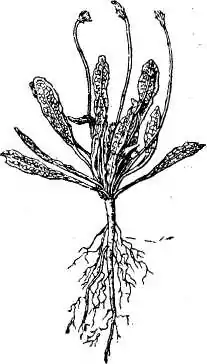

Taraxacum kok-saghyz is a perennial plant with a yellow composite flower characteristic of the genus Taraxacum. Each flower head may be approximately one inch in diameter and be made up for 50 to 90 florets.[6] Plants may contain 25 to 50 leaves arranged in one or more rosettes at the upper end of the root. Taraxacum kok-saghyz can be differentiated from the common dandelion (Taraxacum officinale) by its generally smaller, grayish green leaves and hornlike structures on the bracts surrounding the bud.[6] Flowers are hermaphrodite, insect-pollinated (entomophilous) and are on stalks that reach about a foot in height. Taraxacum kok-saghyz is usually in flower from May through June, with seeds ripening from June through July.[7]

It is a diploid species that reproduces sexually,[2] and produces good pollen.[1] Another species, a triploid apomict that also has horned bracts and produces rubber, T. brevicorniculatum Korol. has frequently been misidentified as T. kok-saghyz.[1][2]

History

TKS was cultivated on a large scale in the Soviet Union during World War II. The Soviet Union cultivated Taraxacum kok-saghyz, together with Taraxacum hybernum and Scorzonera tau-saghyz, on a large scale between 1931 and 1950—notably during World War II—as an emergency source of rubber when supplies of rubber from Hevea brasiliensis in Southeast Asia were threatened. The United States, the UK, Germany, Sweden and Spain also cultivated the plant for the same reason. During this time period, the highest yields achieved by the U.S. reached 110 kg of rubber per hectare, while the USSR achieved yields of 200 kg of rubber per hectare. The Raisko sub-camp of Auschwitz was a production factory for the plant. Some of the women who have been deported on the Convoi des 31000 worked on its production there.[8] With the conclusion of World War II and the return of affordable Hevea brasiliensis rubber (which has 8 to 10 times the yield[9]), the majority of T. kok-saghyz programs ceased.

Growth and cultivation

Growing conditions

Taraxacum kok-saghyz does best in loose, well-drained soils with high moisture retention and a pH between 5.5 and 8.5, in full or nearly-full sun.[7] The plant grows well in temperate climates.[10] The greatest growth is recorded in soils containing 2–8% organic matter.[11]

Seeding

TKS produces about 1 million seeds per pound.[10] The seeds readily germinate but grow very slowly despite the early development of a strong root system. Because of their slow growth, the seedlings are vulnerable to being outcompeted by native weeds. Slow growth and weed control remain major challenges in successfully growing TKS today.[12] The direct seeding of TKS has been identified by researchers as the preferred method for establishing a crop.[10] Field studies showed that TKS germination occurs in May.[13] The vulnerability during early life stages is the main reason why the pest risk assessment, conducted by the Julius Kühn institute, revealed little invasive potential for TKS in Germany.[14]

Challenges

Currently, the main challenges of growing TKS include plant germination, seedling vigor, growth rate, and weed control. Weed control is ineffective, as current available herbicides often have undesired side effects such as slowing the plant development or cause plant injuries.[15] However, weed control is inevitable as uncontrolled weed pressure reduces crop survival and plant growth rate. In addition, the cultivation of TKS in rows is impractical due to the morphology of the plant. Current studies of plant genome aim to identify genetic markers to improve TKS germplasm. Moreover, the development of weed resistance through traditional plant breeding techniques is being investigated.[10]

Pests and disease

In 2022, scientists have reported the first rust disease on TKS in China, caused by Puccinia hieracii. It leads to moderate to high yield losses and poses a potential threat for large scale production of TKS.[16]

Harvest

TKS can be harvested after a single growing season. Rubber accumulation begins at germination, peaks at around one year, and then levels off or decreases due to older root tissues being shed and destroyed by microorganisms.[17]

Utility

Rubber

Natural rubber (cis-1,4-polyisoprene) is a polymer produced by plants. Natural rubber is obtained from coagulating and refining latex from plant species.[10] In many of its most significant applications, it cannot be replaced by synthetic rubber alternatives.[4] Some of the unique and unreplaceable properties include abrasion resistance, elasticity, tear and impact resistance, malleability at cold temperatures, and efficient heat dispersion.[18] The production of natural rubber is concentrated in the tropical areas of Asian-Pacific countries, and it comes from the Para rubber tree (Hevea brasiliensis).[19] The natural rubber market is coordinated by the Association of Natural Rubber Producing Countries (ANRPC). This intergovernmental association represents 92% of the world's natural rubber production.[20] There are a number of factors driving the search for alternatives to natural rubber production.

One threat to Hevea brasiliensis rubber production is the South American Leaf Blight (SALB) caused by Pseudocercospora ulei fungi, which has afflicted conventional rubber production in South America since 1934. This blight may spread to the Hevea brasiliensis trees in Southeast Asia, which are genetically very similar to each other and to those of South America. Furthermore, land used for rubber production is being converted to palm-oil plantations in order to produce biofuel, and labor costs reduce the profitability of Hevea brasiliensis plantations, as each tree must be manually tapped in order to harvest its latex. Rising oil-prices limit the economic viability of synthetic rubbers, and synthetic equivalents often cannot pragmatically replace natural rubber.[4][2] In May 2019 German tire-maker Continental AG announced it was about to begin production of the "first bicycle tyre made with sustainable rubber from dandelions", which it intended to grow on the grounds of its own manufacturing plants, avoiding several of the traditional issues with H. brasiliensis latex—from the long lead-time between planting and cultivating (only six months for the dandelion, rather than seven years for the rubber tree) and volatile prices of the product due to the long transport-distances between places where the rubber can be grown and the company's factories.[21]

Additionally, there are increasing evidence of allergenic reactions to Hevea rubber used in medical devices (gloves, condoms, catheters, and other medical products), potential shortages of supply due to increasing demand (The global market of natural rubber increases annually by 1- 3%.[20]), changes in land use, and a general trend towards the replacement of petroleum-derived chemicals with renewables, which are pushing the search for new sources of natural rubber.[1][4]

One of the alternative options is TKS. It contains on average 12% natural rubber and has an average yield of 225–750 kg/ha. Compared to hevea brasiliensis, the yield of TKS is not enough to cover the cost of both collection and processing.[20] Researchers have started to develop Taraxacum kok-saghyz cultivars which are easier to cultivate and which produce more and better rubber as part of a large research project at many institutions.[9][22][2]

Storage

An important stage of the rubber production that also plays a role in the success of the TKS as a crop, is the storage of the roots. They should be stored and handled differently depending on the dimension of the roots and the harvesting season. In general, dry roots can be stored for at least nine months in a dry environment. In order to maximise the productivity, small roots (under 10 g fresh weight) are processed or dried immediately after harvesting. For large roots it is better to store them fresh in a refrigerated room. Cold conditions, besides stabilizing the rubber content, also increase the rubber content in the roots due to the cold induction of the rubber biosynthetic pathway. This is especially important if the harvest time is before the cold season.[23]

Processing

Right after harvesting, the roots are washed from dirt and soil. If roots are not directly processed, because of transportation reason, they must be dried and then can be stored for several months under appropriate conditions.

The process of rubber-extraction follows this pattern:

- leach the roots in hot water: it softens the tissue and coagulates the latex in fine filament. Also, this removes the soluble carbohydrates (mainly inulin), that can be further used for the ethanol production.

- Pebble grinding: loosen the plant tissue and rolls together the rubber filaments, which can be separated from the root solids by passing over a vibrating screen and flotation

- Separation through vibrating screen and flotation: for the separation of the rubber filament from the root solids.

This process recovered well over 90% of the total rubber in the roots. Another processing option would be the extraction of rubber as latex.[4]

Dandelion by-products

Inulin produced by TKS is a sugar that could be used in non-food applications or be turned into bioethanol through fermentation. The remaining plant biomass could be used to produce biogas.[4] If the plant is cultivated for this by-product, it is important that the roots are not stored in refrigerated conditions, because the roots degrade inulin to provide the substrates for rubber biosynthesis.[23]

Breeding

Goals

The growing interest in natural rubber increases the interest in genetically modified organisms. This need is explained by the decrease of natural rubber world resources, the indispensability of natural rubber for industry, and the strategic necessity of a national industry to be independent of the import . The main breeding goals are increasing both the percentage of rubber content in the plant and the vegetative mass of the plant.[20] Compared to other rubber producing plant, the heritability of yield related traits are lower, implying a slower breeding progress for TKS.[24]

Strategies

The rubber percentage and the size of the roots could be increased through open pollinated polycrosses, resulting in doubled rubber yields. The rubber percentage in TKS could potentially be increased through breeding to 15 to 25% of dry weight.[4] Three genes are mainly responsible for the biosynthesis of rubber: REF (rubber elongation factor), SRPP (small rubber particle protein) and CPT (cis-prenyltransferase). The role of these genes was proved in 2016 by the Hevea genome sequence analysis. With the insertion of these genes into the nuclear DNA of TKS, it is possible to increase the content and the quality of rubber in the plant. Genetic engineering allows to increase the rubber content of TKS in two ways: either through inulin degradation by gene 1-FEN expression or through knockdown of the gene fructan 1-fructosyl transferase (1-FFT), which codes for the fructose involved in inulin synthesis.[20] Regarding the competitiveness with weeds, creating herbicide resistant TKS plants is a possible strategy to solve this problem. Hybridization between rubber dandelion TKS and common dandelion (Taraxacum officinale) has been proposed as a possible way to achieve this resistance.[25]

References

- Kirschner, J.; Štěpánek, J.; Černý, T.; Heer, P.; Dijk, P. (2013). "Available ex situ germplasm of the potential rubber crop Taraxacum koksaghyz belongs to a poor rubber producer, T. brevicorniculatum (Compositae–Crepidinae)". Genetic Resources and Crop Evolution. 60 (2): 455–471. doi:10.1007/s10722-012-9848-0. S2CID 16578615.

- Nowicki, Marcin; Zhao, Yichen; Boggess, Sarah L.; Fluess, Helge; Payá-Milans, Miriam; Staton, Margaret E.; Houston, Logan C.; Hadziabdic, Denita; Trigiano, Robert N. (December 2019). "Taraxacum kok-saghyz (rubber dandelion) genomic microsatellite loci reveal modest genetic diversity and cross-amplify broadly to related species". Scientific Reports. 9 (1): 1915. doi:10.1038/s41598-019-38532-8. ISSN 2045-2322. PMC 6374447. PMID 30760810.

- Mayhood, Kevin (July 1, 2008). "Roots to Rubber". The Columbus Dispatch. Archived from the original on 2010-06-08. Retrieved May 1, 2011.

- Van Beilen, Jan B.; Poirier, Yves (2007). "Guayule and Russian Dandelion as Alternative Sources of Natural Rubber". Critical Reviews in Biotechnology. 27 (4): 217–31. doi:10.1080/07388550701775927. PMID 18085463. S2CID 7279687.

- Craymer, Lucy (October 2, 2018). "Dandelions Ruin Your Front Yard but Could Be the Future of the Rubber Industry". Wall Street Journal.

- Whaley, William Gordon; Bowen, John Stevenson (1947). Russian Dandelion (kok-saghyz) An Emergency Source of Natural Rubber. United States Department of Agriculture. p. 12. OCLC 12131809.

- Rodin, L. E. "Taraxacum kok-saghyz". Plants for a Future. Retrieved May 1, 2011.

- Delbo, Charlotte (1997). Convoy to Auschwitz: Women of the French Resistance. Northeastern University Press. ISBN 978-1-55553-313-7.

- "Blow out: The tyres of the future may be made from dandelions". The Economist. December 30, 2009. Retrieved May 1, 2011.

- Keener, Harold M.; Shah, Ajay; Klingman, Mike; Wolfe, Scott; Pote, Dan; Fioritto, Ron (September 2018). "Progress in Direct Seeding of an Alternative Natural Rubber Plant, Taraxacum kok-saghyz (L.E. Rodin)". Agronomy. 8 (9): 182. doi:10.3390/agronomy8090182. ISSN 2073-4395.

- Whaley, W. Gordon; Bowen, John Stevenson (1947). "Russian dandelion (kok-saghyz)".

{{cite journal}}: Cite journal requires|journal=(help) - Krotkov, G. (1945-10-01). "A review of literature onTaraxacum koksaghyz Rod". The Botanical Review. 11 (8): 417–461. doi:10.1007/BF02861139. ISSN 1874-9372. S2CID 9672940.

- Kreuzberger, Marie; Hahn, Thomas; Zibek, Susanne; Schiemann, Joachim; Thiele, Katja (2016-10-01). "Seasonal pattern of biomass and rubber and inulin of wild Russian dandelion (Taraxacum koksaghyz L. Rodin) under experimental field conditions". European Journal of Agronomy. 80: 66–77. doi:10.1016/j.eja.2016.06.011. ISSN 1161-0301.

- "PRA - Pest risk analysis for Taraxum koksaghyz". pra.eppo.int. Retrieved 2022-11-27.

- Bon Robinson, John Cardina; Herbicide Evaluation for Weed Control in Taraxacum kok-saghyz: https://cornishlab.cfaes.ohio-state.edu/sites/hcs-cornishlab/files/imce/Ben-%20Herbicide%20Evaluation%20for%20Weed%20Control%20in%20Taraxacum%20kok-saghyz%20%282016%29.pdf

- Ren, H. L.; Zhang, Y.; Xu, L.; Zhang, X. C.; Han, S.; Maimaiti, Y.; Nie, Q. H. (2021-01-01). "First Report of a Rust Disease Caused by Puccinia hieracii on Taraxacum kok-saghyz in China". Plant Disease. 105 (1): 229. doi:10.1094/PDIS-06-20-1294-PDN. ISSN 0191-2917. S2CID 225628493.

- Bonner, James; Galston, Arthur W. (1947-12-01). "The physiology and biochemistry of rubber formation in plants". The Botanical Review. 13 (10): 543–596. doi:10.1007/BF02861372. ISSN 1874-9372. S2CID 144462.

- Salehi, Maryam; Bahmankar, Moslem; Naghavi, Mohammad Reza; Cornish, Katrina (2022-04-01). "Rubber and latex extraction processes for Taraxacum kok-saghyz". Industrial Crops and Products. 178: 114562. doi:10.1016/j.indcrop.2022.114562. ISSN 0926-6690.

- Molinu, Maria Giovanna; Piluzza, Giovanna; Campesi, Giuseppe; Sulas, Leonardo; Re, Giovanni Antonio (August 2019). "Antioxidant Sources from Leaves of Russian Dandelion". Chemistry & Biodiversity. 16 (8): e1900250. doi:10.1002/cbdv.201900250. ISSN 1612-1872. PMID 31250533. S2CID 195761533.

- Katile L.L; Russian dandelion (Taraxacum kok-saghyz Rodin) as an alternative to hevea (Hevea brasiliensis) for natural rubber production: https://www.researchgate.net/publication/339003572_Russian_dandelion_Taraxacum_kok-saghyz_Rodin_as_an_alternative_to_hevea_Hevea_brasiliensis_for_natural_rubber_production_KATILE_LL

- Smythe, Simon (May 22, 2019). "Continental launches bike tyre made from sustainable dandelion rubber". Cycling Weekly. London. Retrieved August 4, 2019.

-

"About EU-PEARLS". EU-based Production and Exploitation of Alternative Rubber and Latex Sources. Wageningen University and Research. Retrieved August 4, 2019.

The EU-PEARLS consortium links stakeholders in the EU and elsewhere in the development, exploitation and sustainable use of guayule and Russian dandelion, aiming to establish complete new value creation chains for natural rubber and latex from these plants.

- Cornish, K.; Bates, G. M.; Mcnulty, S. K.; Kopicky, S. E.; Grewal, S.; Rossington, Jesse; Michel, F.; Walker, S. (2013). "A study into rubber production in Taraxacum kok-saghyz with an emphasis on post-harvest storage". www.semanticscholar.org. S2CID 219173091. Retrieved 2022-11-27.

- Luo, Zinan; Iaffaldano, Brian J.; Zhuang, Xiaofeng; Fresnedo-Ramírez, Jonathan; Cornish, Katrina (2018-08-01). "Variance, Inter-Trait Correlation, Heritability, and Marker-Trait Association of Rubber Yield-Related Characteristics in Taraxacum kok-saghyz". Plant Molecular Biology Reporter. 36 (4): 576–587. doi:10.1007/s11105-018-1097-8. ISSN 1572-9818. S2CID 254944852.

- Iaffaldano, Brian; Cardina, John; Cornish, Katrina (February 2018). "Hybridization potential between the rubber dandelion Taraxacum kok‐saghyz and common dandelion Taraxacum officinale". Ecosphere. 9 (2). doi:10.1002/ecs2.2115. ISSN 2150-8925.

Further reading

- Wahler, Daniela; Gronover, Christian Schulze; Richter, Carolin; Foucu, Florence; Twyman, Richard M.; Moerschbacher, Bruno M.; Fischer, Rainer; Muth, Jost; Prufer, Dirk (2009). "Polyphenoloxidase Silencing Affects Latex Coagulation in Taraxacum Species". Plant Physiology. 151 (1): 334–46. doi:10.1104/pp.109.138743. PMC 2736003. PMID 19605551.

- Krotkov, G. (1950). "Changes in the Carbohydrate Metabolism of Taraxacum Kok-Saghyz Rod During the First and Second Years of Growth". Plant Physiology. 25 (1): 169–80. doi:10.1104/pp.25.1.169. PMC 438030. PMID 16654275.