Syngas to gasoline plus

Syngas to gasoline plus (STG+) is a thermochemical process to convert natural gas, other gaseous hydrocarbons or gasified biomass into drop-in fuels, such as gasoline, diesel fuel or jet fuel, and organic solvents.

Process chemistry

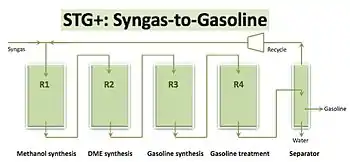

This process follows four principal steps in one continuous integrated loop, comprising four fixed bed reactors in a series in which a syngas is converted to synthetic fuels. The steps for producing high-octane synthetic gasoline are as follows:[1]

- Methanol Synthesis: Syngas is fed to Reactor 1, the first of four reactors, which converts most of the syngas to methanol when passing through the catalyst bed.

- CO + 2 H2 →

- Dimethyl Ether (DME) Synthesis: The methanol-rich gas from Reactor 1 is next fed to Reactor 2, the second STG+ reactor. The methanol is exposed to a catalyst and much of it is converted to DME, which involves a dehydration from methanol to form DME.

- 2 CH3OH → CH3OCH3 + H2O

- Gasoline synthesis: The Reactor 2 product gas is next fed to Reactor 3, the third reactor containing the catalyst for conversion of DME to hydrocarbons including paraffins (alkanes), aromatics, naphthenes (cycloalkanes) and small amounts of olefins (alkenes), typically with the carbon number ranging from 6 to 10.

- Gasoline Treatment: The fourth reactor provides transalkylation and hydrogenation treatment to the products coming from Reactor 3. The treatment reduces durene/isodurene (tetramethylbenzenes) and trimethylbenzene components that have high freezing points and must be minimized in gasoline. As a result, the synthetic gasoline product has high octane and desirable viscometric properties.

- Separator: Finally, the mixture from Reactor 4 is condensed to obtain gasoline. The non-condensed gas and gasoline are separated in a conventional condenser/separator. Most of the non-condensed gas from the product separator becomes recycled gas and is sent back to the feed stream to Reactor 1, leaving the synthetic gasoline product composed of paraffins, aromatics and naphthenes.

Catalysts

The STG+ process uses standard catalysts similar to those used in other gas to liquids technologies, specifically in methanol to gasoline processes. Methanol to gasoline processes favor molecular size- and shape-selective zeolite catalysts,[2] and the STG+ process also utilizes commercially available shape-selective catalysts, such as ZSM-5.[3]

Process efficiency

According to Primus Green Energy, the STG+ process converts natural gas into 90+-octane gasoline at approximately 5 US gallons per million British thermal units (65 litres per megawatt-hour).[4] The energy content of gasoline is 120,000 to 125,000 British thermal units per US gallon (9.3 to 9.7 kilowatt-hours per litre), making this process about 60% efficient, with a 40% loss of energy.

Gasification

As is the case with other gas to liquids processes, STG+ utilizes syngas produced via other technologies as a feedstock. This syngas can be produced through several commercially available technologies and from a wide variety of feedstocks, including natural gas, biomass and municipal solid waste.

Natural gas and other methane-rich gases, including those produced from municipal waste, are converted into syngas through methane reforming technologies such as steam methane reforming and auto-thermal reforming.

Biomass gasification technologies are less established, though several systems being developed utilize fixed bed or fluidized bed reactors.[5]

Comparison to other GTL technologies

Other technologies for syngas to liquid fuels synthesis include the Fischer–Tropsch process and the methanol to gasoline processes.

Research conducted at Princeton University indicates that methanol to gasoline processes are consistently more cost-effective, both in capital cost and overall cost, than the Fischer–Tropsch process at small, medium and large scales.[6] Preliminary studies suggest that the STG+ process is more energetically efficient and the highest yielding methanol to gasoline process.[7]

Fischer–Tropsch process

The primary difference between the Fischer–Tropsch process and methanol to gasoline processes such as STG+ are the catalysts used, product types and economics.

Generally, the Fischer–Tropsch process favors unselective cobalt and iron catalysts, while methanol to gasoline technologies favor molecular size- and shape-selective zeolites.[8] In terms of product types, Fischer–Tropsch production has been limited to linear paraffins,[8] such as synthetic crude oil, whereas methanol to gasoline processes can produce aromatics, such as xylene and toluene, and naphthenes and iso-paraffins, such as drop-in gasoline and jet fuel.

The main product of the Fischer–Tropsch process, synthetic crude oil, requires additional refining to produce fuel products such as diesel fuel or gasoline. This refining typically adds additional costs, causing some industry leaders to label the economics of commercial-scale Fischer–Tropsch processes as challenging.[9]

Methanol to gasoline

The STG+ technology offers several differentiators that distinguish it from other methanol to gasoline processes. These differences include product flexibility, durene reduction, environmental footprint and capital cost.

Traditional methanol to gasoline technologies produce diesel, gasoline or liquefied petroleum gas.[10] STG+ produces gasoline, diesel, jet fuel and aromatics, depending on the catalysts used. The STG+ technology also incorporates durene reduction into its core process, meaning that the entire fuel production process requires only two steps: syngas production and gas to liquids synthesis.[1] Other methanol to gasoline processes do not incorporate durene reduction into the core process, and they require the implementation of an additional refining step.[10]

Due to the additional number of reactors, traditional methanol to gasoline processes include inefficiencies such as the additional cost and energy loss of condensing and evaporating the methanol prior to feeding it to the durene reduction unit.[11] These inefficiencies can lead to a greater capital cost and environmental footprint than methanol to gasoline processes that use fewer reactors, such as STG+. The STG+ process eliminates multiple condensation and evaporation, and the process converts syngas to liquid transportation fuels directly without producing intermediate liquids.[7] This eliminates the need for storage of two products, including pressure storage for liquefied petroleum gas and storage of liquid methanol.

Simplifying a gas to liquids process by combining multiple steps into fewer reactors leads to increased yield and efficiency, enabling less expensive facilities that are more easily scaled.[12]

Commercialization

The STG+ technology is currently operating at pre-commercial scale in Hillsborough, New Jersey at a plant owned by alternative fuels company Primus Green Energy. The plant produces approximately 100,000 gallons of high-quality, drop-in gasoline per year directly from natural gas.[13] Further, the company announced the findings of an independent engineer’s report prepared by E3 Consulting, which found that STG+ system and catalyst performance exceeded expectations during plant operation. The pre-commercial demonstration plant has also achieved 720 hours of continuous operation.[14]

Primus Green Energy has announced plans to break ground on its first commercial STG+ plant in the second half of 2014, and the company has announced that this plant is expected to produce approximately 27.8 million gallons of fuel annually.[15]

In early 2014, the U.S. Patent and Trademark Office (USPTO) allowed Primus Green Energy’s patent covering its single-loop STG+ technology.[15]

References

- Introduction to STG+ Technology Primus Green Energy, February 2013. Retrieved: 5 March 2013.

- http://www.dgmk.de/petrochemistry/abstracts_content16/Dathe.pdf H. Dathe, K.-F. Finger, A. Haas, P. Kolb, A. Sundermann and G. Wasserschaff. "High Throughput Catalyst Optimization Program for the GTL-Technologies MTG, HAS and FTS", DBMK/SCI/ÖGEW Conference, October, 2008.

- http://www.wpi.edu/Pubs/E-project/Available/E-project-022813-170709/unrestricted/Primus_Green_Energy_IQP.pdf D. Tocco, S. Miraglia and J. Giesecke. "Primus Green Energy", Worcester Polytechnic Institute, March, 2013.

- "STG+ Technology". www.primusge.com. Archived from the original on 21 February 2013.

- D. Peterson and S. Haase (July 2009). Market Assessment of Biomass Gasification and Combustion Technology for Small- and Medium-Scale Applications (PDF) (Report). National Renewable Energy Laboratory. p. 9. Retrieved 30 April 2013.

- Richard C. Baliban, Josephine A. Elia, Vern Weekman, and Christodoulos A. Floudas "Process Synthesis of Hybrid Coal, Biomass, and Natural Gas to Liquids via Fischer–Tropsch Synthesis, ZSM-5 Catalytic Conversion, Methanol Syntehsis, Methanol-to-Gasoline, and Methanol-to-Olefins/Distillate Technologies" in Computers & Chemical Engineering, 2012, Elsevier. doi:10.1016/j.compchemeng.2012.06.032

- Comparison of STG+ With Other GTL Technologies Primus Green Energy, April 2013. Retrieved: 29 April 2013.

- Eduardo Falabella Sousa-Aguiar, Fabio Bellot Noronha, and Arnaldo Faro, Jr. "The Main Catalytic Challenges in GTL (Gas-to-Liquids) Processes" in Catalysis Science & Technology, 2011, RSC. doi:10.1039/C1CY00116G

- Broder, John M. and Clifford Krauss. A Big, and Risky, Energy Bet The New York Times, 17 December 2012. Retrieved: 15 April 2013.

- Methanol to Gasoline (MTG) Production of Clean Gasoline from Coal ExxonMobil, December 2009. Retrieved: 30 April 2013.

- Liquid Transportation Fuels from Coal and Biomass: Technological Status, Costs, and Environmental Impacts (Report). The National Academies Press. 2009. Retrieved 25 April 2013.

- Richard C. Baliban, Josephine A. Elia, and Christodoulos A. Floudas "Novel Natural Gas to Liquids Processes: Process Synthesis and Global Optimization Strategies" in American Institute of Chemical Engineers Journal, 2013, AIChE. doi:10.1002/aic.13996

- "Primus Green Energy".

- "Technologies". www.e3co.com. Archived from the original on 9 April 2014.

- "Primus Green Energy".