Front end of line

The front-end-of-line (FEOL) is the first portion of IC fabrication where the individual components (transistors, capacitors, resistors, etc.) are patterned in the semiconductor.[1] FEOL generally covers everything up to (but not including) the deposition of metal interconnect layers.[2]

.svg.png.webp)

BEOL (metalization layer) and FEOL (devices).

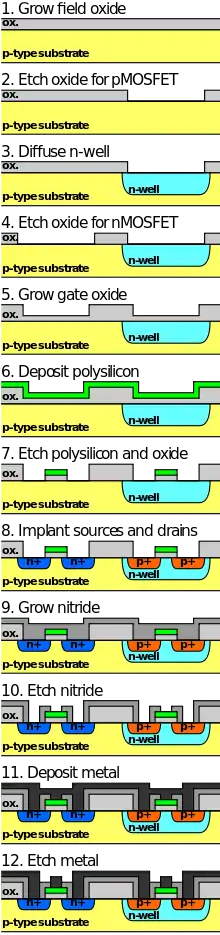

CMOS fabrication process

For the CMOS process, FEOL contains all fabrication steps needed to form isolated CMOS elements:[3]

- Selecting the type of wafer to be used; Chemical-mechanical planarization and cleaning of the wafer.

- Shallow trench isolation (STI) (or LOCOS in early processes, with feature size > 0.25 μm)

- Well formation

- Gate module formation

- Source and drain module formation

See also

References

- Karen A. Reinhardt and Werner Kern (2008). Handbook of Silicon Wafer Cleaning Technology (2nd ed.). William Andrew. p. 202. ISBN 978-0-8155-1554-8.

- "FEOL (Front End of Line: substrate process, the first half of wafer processing) 1. Isolation | USJC:United Semiconductor Japan Co., Ltd". USJC:United Semiconductor Japan Co., Ltd. | 三重県桑名市の300mm半導体ウェーハ工場を製造拠点にしたファウンドリ専業メーカーです。超低消費電力、不揮発メモリなど先進テクノロジーを世界中のお客様に提供しています。 (in Japanese). 2019-02-22. Retrieved 2022-09-27.

- Ramsundar, Bharath. "A Deep Dive into Chip Manufacturing: Front End of Line (FEOL) Basics". deepforest.substack.com. Retrieved 2022-09-27.

Further reading

- "CMOS: Circuit Design, Layout, and Simulation" Wiley-IEEE, 2010. ISBN 978-0-470-88132-3. pages 177-178 (Chapter 7.2 CMOS Process Integration); pages 180-199 (7.2.1 Frontend-of-the-line integration)

This article is issued from Wikipedia. The text is licensed under Creative Commons - Attribution - Sharealike. Additional terms may apply for the media files.