Cotton bale

A Cotton bale is a standard-sized and weighted pack of compressed cotton lint after ginning. The dimensions and weight may vary with different cotton-producing countries.[1]

Significance

A bale has an essential role from the farm to the factory. The cotton yield is calculated in terms of the number of bales.[2] Bale is a standard packaging method for cotton to avoid various hassles in handling, packing, and transportation. The bales also protect the lint from foreign contamination and make them readily identifiable.[3]

Cotton bale management system

Bale management encompasses the systematic procedures of categorizing, blending, and assessing bales based on fiber attributes, with the aim of achieving desired quality yarn production at an optimized cost.[4] Cotton fibres differ in terms of staple length and other physical characteristics; this is an inherent feature.[5] Bale management, also known as "bale mixing," is the process of analysing, classifying, and then blending fibres from various bales [which also includes the bales received from other stations] according to their fibre properties in order to create yarn of a specific quality at the most affordable price.[6]

Standards

Bale

A "bale of cotton" is also the standard trading unit for cotton on the wholesale national and international markets. Although different cotton-growing countries have their bale standards, for example, In the United States, cotton is usually measured at approximately 0.48 cubic meters (17 cu ft) and weighs 226.8 kilograms (500 pounds).[7] In India, the standard bale size is 170 kg.[8][9][10][11]

Parameters

The most important parameters of a cotton bale are:

- Density (448 kg/m3)[10]

- Measurements of the bales (nominally 1.40 m X 0.53 m X 0.69 m)[12][10]

- Weight (Varies, but ‘statistical’ bale weighs 480 lb)[10]

| Sr.No. | Country | Bale in kg |

|---|---|---|

| 1 | Australia | 227 |

| 2 | Colombia | 233 |

| 3 | Egypt | 327 |

| 4 | India | 170[13] |

| 5 | Pakistan | 170 |

| 6 | Mexico | 230 |

| 7 | Nigeria | 185 |

| 8 | South Africa | 200 |

| 9 | Sudan | 191 |

| 10 | Tanzania | 181 |

| 11 | Uganda | 181 |

| 12 | United States of America | 225 |

Advances in standardization are reducing the variation in weights, sizes, dimensions, and densities of cotton bales.[8][14]

Trash

When cotton is harvested and exposed to ginning, it carries more than 64% cottonseed, 2% waste and 34% fibrous matter (also known as lint).[18] Lower trash percentage in cotton increases the recovery.[19] Cotton bales are not pure cotton; they contain foreign contaminants, residual trash and leaf (and other non lint material) that have a direct impact on the recovery in yarn spinning.[20][21]

Gallery

Cotton cultivation

Cotton Field at Singalandapuram, Rasipuram, India (2017)

Cotton Field at Singalandapuram, Rasipuram, India (2017) Cotton field

Cotton field Cotton plant

Cotton plant

Harvesting

_READY_FOR_HARVEST.jpg.webp)

A cotton field, late in the season

A cotton field, late in the season

Picking cotton in Armenia in the 1930s. No cotton is grown there today.

Picking cotton in Armenia in the 1930s. No cotton is grown there today. A group of Egyptian fellahs picking cotton by hand

A group of Egyptian fellahs picking cotton by hand-06.jpg.webp) Hand picking cotton (Tashkent, Uzbekistan)

Hand picking cotton (Tashkent, Uzbekistan) A module builder

A module builder%252CUS_wed01jan2014-1557h.jpg.webp) Cotton modules in a harvested cotton field (Clinch County, Georgia, USA, January 2014).

Cotton modules in a harvested cotton field (Clinch County, Georgia, USA, January 2014). Case IH Module Express 625 picks cotton and simultaneously builds cotton modules

Case IH Module Express 625 picks cotton and simultaneously builds cotton modules Cotton modules in Australia (2007)

Cotton modules in Australia (2007)

Ginning and bale making

A model of a 19th-century cotton gin on display at the Eli Whitney Museum in Hamden, Connecticut

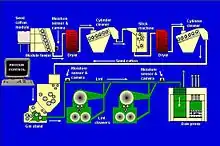

A model of a 19th-century cotton gin on display at the Eli Whitney Museum in Hamden, Connecticut Diagram of a modern cotton gin plant, displaying numerous stages of production

Diagram of a modern cotton gin plant, displaying numerous stages of production Modern ginning machines in working

Modern ginning machines in working

Cotton ready for shipment, Houston, Texas (postcard, circa 1911)

Cotton ready for shipment, Houston, Texas (postcard, circa 1911)

See also

References

- Turner, Joseph Addison (1865). The Cotton Planter's Manual: Being a Compilation of Facts from the Best Authorities on the Culture of Cotton; Its Natural History, Chemical Analysis, Trade, and Consumption; and Embracing a History of Cotton and the Cotton Gin. Judd. p. 273.

- "Cotton Corporation of India". cotcorp.org.in. Retrieved 2021-02-24.

- Standardized Bales of Cotton: Hearing, Seventieth Congress, First Session, on S. 872, a Bill to Standardize Bales of Cotton and Requiring Sale of Cotton by the True Net Weight of Bale. May 16, 1928. United States Congress Senate Committee on Agriculture and Forestry. U.S. Government Printing Office. 1928. p. 100.

{{cite book}}: CS1 maint: others (link) - Kumar, R. Senthil (2014-09-23). Process Management in Spinning. CRC Press. pp. 15, 16, 17. ISBN 978-1-4822-0836-8.

- admin (2022-01-28). "Yarn recovery: The He(art) of spinning". Indian Textile Journal. Retrieved 2023-06-25.

- "Bale Opener - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2023-06-25.

- National Cotton Council of America, "U.S. Cotton Bale Dimensions Archived 6 October 2013 at the Wayback Machine" (accessed 5 October 2013).

- "Cotton imports may rise four fold as record exports deplete stocks". The Financial Express. 2012-09-21. Retrieved 2021-02-24.

- "Cotton - International Year of Natural Fibres". 2011-09-03. Archived from the original on 2011-09-03. Retrieved 2021-02-24.

- "Measurements - The Farm Hub - Textile Exchange". farmhub.textileexchange.org. Retrieved 2021-02-25.

- "Conversion factors". www.cottonguide.org. Retrieved 2021-02-25.

- "U.S. Cotton Fiber Chart - Bale Sizes". Cotton Incorporated. Retrieved 2021-02-25.

- Cotton Sector

- "ISO 8115:1986". ISO. Retrieved 2021-02-25.

- "MCX traders can see cotton prices in candy too". Business Standard India. Press Trust of India. 2017-04-09. Retrieved 2021-11-01.

- Vora, Rutam. "Cotton trade may soon have uniform unit of measurement". @businessline. Retrieved 2021-02-24.

- "Cotton Rate, Today's Cotton Price in India: Cotton News on Economic Times". The Economic Times. Retrieved 2021-02-25.

- Akroyd, H. David (2017-10-24). Agriculture and Rural Development Planning: A Process in Transition. Routledge. p. 260. ISBN 978-1-351-96010-6.

- Kolanjikombil, Mathews (2018). The Substrates: Fibres, Yarn and Fabrics. Woodhead Publishing India Pvt Limited. p. 21. ISBN 978-93-85059-90-2.

- The Classification of Cotton. United States Agricultural Marketing Service Cotton Division. U.S. Department of Agriculture. 1965. p. 9.

{{cite book}}: CS1 maint: others (link) - Morris, John; Wilkinson, F. W. (1897). The Elements of Cotton Spinning. Longmans.