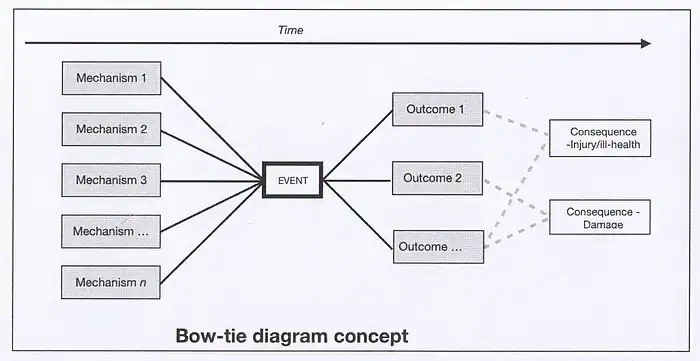

Bow-tie diagram

A bow-tie diagram is a graphic tool used to simplify understanding of the process leading to damage or loss. The diagram records the results of an analysis based on a defined Event and shows all of the physically possible Mechanisms to the left of the Event and the physically possible Outcomes of the Event on the right. The shape of the diagram resembles that of a bow tie, after which it is named.[3]

The bow-tie diagram can be used proactively to record the identification and analysis all possible damage processes in a particular situation and act as an index of the various features of design and management systems that control the risk of such processes. They may also be used to contribute to the structure of an analysis of an Event that has occurred (an 'accident' analysis). In this way the bow-tie diagram is useful for a structured overview of all sources of risk.[1]

The diagram follows the same basic principles as those on which fault tree analysis and event tree analysis are based,[2] but, in being far less complex than these, is attractive as a means of rapidly establishing an overall scope of risk concerns for an organisation, only some few of which may justify those more rigorous and logical methods.[2][3][4]

Bow-tie diagrams are used to analyze and manage risk in several industries, such as oil and gas production, the process industries, aviation, and finance.[1][5][6]

History

It is generally accepted in the literature that the earliest public mention[1][7] of the bow-tie diagram appeared in Imperial Chemical Industries (ICI) course notes. However, Viner[3] explains how the diagram originally arose in a lecture on damage process modelling given by him in Australia at the then Ballarat College of Advanced Education (now the Federation University), which lecture was attended by students from ICI. This diagrammatic representation of the damage process was developed spontaneously during a lecture on the Generalised Time Sequence Model (GTSM) of the damage process, in order to facilitate, by its simplicity, student understanding of damage process models.[8][3]

Royal Dutch Shell is considered to be the first major company to successfully integrate bow-tie diagrams into their business practices, at least since the early 1990s.[1][9][10]

Explanation and structure of the diagram

Bow-tie diagrams contribute to the identification, description and understanding of the different processes that can give rise to injury, ill-health, damage and loss in a given situation. This understanding helps in the identification and management over time of required risk control measures.[4]

The fact that scientific effort[8] benefits greatly from a focus on the process leading to the phenomenon of interest is well known in several scientific domains, as was noted by Haddon.[11] The GTSM, introduced by Viner,[3] is a generic process model suited to processes involving an initiating event. Simply put, Events arise for physically possible reasons and having arisen various physically possible Outcomes may develop and it is these latter that result in the phenomenon of unwanted Consequences of damage and loss, which is the phenomenon of interest in the field of risk engineering and management.

Rowe introduced the idea of events leading to outcomes of relevance in his seminal work on risk.[12] In this, the event of interest is defined as what produces outcomes and consequences of interest and outcomes as what results from an event. Viner[3] resolved this circularity by defining the Event as "the point in time when control is lost of the potentially damaging properties of the energy source of interest". The fact that an energy source is a necessary prerequisite for damage is not only obvious to a physical scientist but attention has been drawn to it in the literature of this subject for nearly 100 years: see for early origins the work of Deblois,[13] Gibson,[14] and Haddon.[11]

The bow-tie diagram is hence centred on a defined Event[3]. This is necessarily energy-based if the Consequences of interest include injury, ill-health and/or damage and associated financial losses[3]. It may be non-energy based if the only possible Consequences are loss directly, for example failure of a sole supplier on which a business relies[3][6]. The physically possible Mechanisms (reasons) for the Event are shown to the left of the Event, to indicate that they precede it in time. In a similar way, the physically possible Outcomes (results) of the Event are shown in the diagram to the right of it, to indicate that they follow from the Event. The diagram may also show Consequences arising from the outcomes[3]. The GTSM, the bow-tie diagram being a visual simplification of part of it, also notes the presence of the pre-requisites of each Mechanism and this feature may be included in a bow-tie model[3]. These left to right protocols emphasise the time based nature of the process. The GTSM and hence also the bow-tie diagram, allows for the definition and understanding of the related factors that influence associated probabilities and Consequence values, namely risk factors.[3]

The definitions that underly bow-tie diagrams are equally applicable to fault tree analysis and event tree analysis. By defining the Event of interest as described here, a fault tree analysis of the Mechanisms and Event tree analysis of the Outcomes may be added to the left and right of the Event respectively to produce a damage process model that is capable of being quantified using real number values[3].[4]

The value of the bow-tie diagram lies in the facts that:

- its development demands logical analysis and as errors or omissions in this are discovered over time it provides a place for these to be captured, thereby capitalising on the effort

- what may be a complex analysis can be understood at a glance

- each pathway line to the left and right of the Event suggests a possibility for identifying risk control measures aimed at removing or reducing the likelihood of that pathway.

Example

The diagram above is based on an Event associated with chemical bonding energy and for the purpose of considering personal injury of exposed susceptible people (or other asset). The Event would be carefully defined as "the point in time when control is lost over the potentially damaging toxic properties associated with the chemical bonding energy".[3] If this chemical is contained in some way in space, control will be lost either if the containment fails or if a susceptible asset (a person for example) enters the space. The simplified Event name "Un-contained chemical" is practical as a mnemonic on the diagram but should always be associated with the proper full definition and explanation.

"Containment" as defined here can fail in various ways (Mechanisms), for example:

- failure of the containment structure or the chemical being released (eg. through a valve) due to either human or automated controller action. Containment structural failure may be due to the deterioration of the structure resulting from mechanisms such as corrosion, abrasion, fatigue, embrittlement, UV exposure or to the overloading of the structure (eg. by external impact, uncontrolled pressure rise, unlimited filling etc.)

- a vessel containing the chemical is entered, either inadvertently or intentionally.

A susceptible person or other asset may be exposed to the damaging properties of the contained substance by Outcomes involving the transfer of the chemical from the containment space to the location of the susceptible person (or the person enters the space occupied by the chemical) and subsequently into the person by means of:

- ingestion (or injection)

- inhalation

- absorption through the skin (eg. from splash or spray or being deluged by the chemical).

All lists of Outcomes should include a "Null Outcome". Null Outcomes are common and often thought of as a "near miss".[3] In this example, a Null Outcome may mean the pathways to the susceptible person are rapidly terminated or that the person rapidly escapes from the un-contained movement of chemical or escapes from the containment vessel.

Consequences arising from exposure through these Outcomes may include:

- acute toxic effects, eg. suffocation, chemical burns

- chronic toxic effects, eg. sensitisation, long-latency diseases

It will be evident that the meaning of the diagram is conveyed mostly in the explanatory words[4] and that the diagram itself facilitates understanding at a glance.

Cautions

The bow-tie diagram has been widely adopted[3] and given rise to various software aids to its use. Other than the general appearance of the diagram, there is no guarantee that users adhere to any discipline or use meaningful definitions.[4] Terms may be introduced that result in unclear meaning and possibly confused analysis. In this regard, it is tempting for it to be used as a scaffold for accident and cause-effect ideas[3], neither of which satisfy the demands of science and engineering for rigour and objective definition.

The event in a bow-tie analysis may be referred to as the top event (a term borrowed from fault tree analysis) or the critical event, (a scope-limiting term in this context).[4]

Other terms found in software or training aids may include:

- hazard and hazardous, which can mean numerous things either to the left of the event, the event itself, or to the right of the event

- trigger, possibly and often unambiguously, used as a synonym of Mechanism/Reason

- threat, possibly used as an alternative to either Mechanism or Event. "Threat" is a good generic term that can encompass both energy and non-energy based[6] damage processes.

Software applications exist that replace the term 'Outcome' with 'Consequence'. An understanding of the difference between these two terms is essential to any meaningful use of the diagram.[4][3]

Use in various domains

Bow-tie diagrams are used in various disciplines and domains, including for example:

- Occupational safety and health (OSH)[1][8]

- Process safety[1]

- Aviation safety[5]

- Information security and cyber security risks[6]

- Finance[1]

Several software packages are available to facilitate the creation of bow-tie diagrams.

References

- Center for Chemical Process Safety in association with Energy Institute (2018). Bow Ties in Risk Management. Hoboken, N.J.: John Wiley & Sons. ISBN 9781119490388.

- IEC; ISO (2019). Risk Management – Risk Assessment Techniques. IEC 31010 (2.0 ed.). Geneva: International Electrotechnical Commission. ISBN 978-2-8322-6989-3.

{{cite book}}: CS1 maint: multiple names: authors list (link) - Viner, Derek (2015). Occupational Risk Control: Predicting and Preventing the Unwanted. Routledge. ISBN 978-1-4724-1970-5.

- de Ruijter, A.; Guldenmund, F. (2016). "The Bowtie Method: A Review". Safety Science. 88: 211–218. doi:10.1016/j.ssci.2016.03.001.

- "Introduction to Bowtie". UK Civil Aviation Authority. Retrieved 2023-07-14.

- Bernsmed, K.; Frøystad, C.; Meland, P.H.; Nesheim, D.A.; Rødseth, Ø.J. (2018). "Visualizing Cyber Security Risks with Bow-Tie Diagrams". In Liu, P.; Mauw, S.; Stolen, K. (eds.). Graphical Models for Security. 4th International Workshop, GraMSec 2017, Santa Barbara, CA, USA, August 21, 2017, Revised Selected Papers. Springer, Cham. ISBN 978-3-319-74860-3.

- "Bowties - History". BowTie Pro. Archived from the original on 2016-06-17.

- Donaldson, Craig (2016). "Time for OHS to Understand the Science of Risk". OHS Professional (December 2016): 18–22.

- Sneddon, James. "Practical Application of Bowtie Analysis" (PDF). Chemical Institute of Canada. Retrieved 2023-07-14.

- Rausand, Marvin (2011). Risk Assessment: Theory, Methods, and Applications. Hoboken, N.J.: John Wiley & Sons. ISBN 978-0-470-63764-7.

- Haddon, Jr., William (1973). "Energy Damage and the Ten Countermeasure Strategies". Human Factors. 15 (4): 355–366. doi:10.1177/001872087301500407.

- Rowe, William D. (1977). An Anatomy of Risk. John Wiley & Sons.

- DeBlois, Lewis Amory (1926). Industrial Safety Organization for Executive and Engineer. McGraw-Hill Book Company.

- Gibson, J. (1961). "The Contribution of Experimental Psychology to the Formulation of the Problem of Safety – A Letter for Basic Research". In Jacobs, Herbert J. (ed.). Behavioral Approaches to Accident Research. New York, N.Y.: Association for the Aid of Crippled Children.