|

Cucina 012 Knife set |

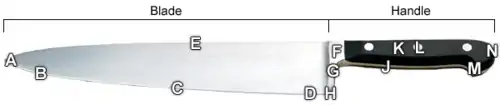

Knife Construction

| A | Point: | The very end of the knife, which is used for piercing |

| B | Tip: | The first third of the blade (approximately), which is used for small or delicate work. Also known as belly or curve when curved, as on a chef's knife. |

| C | Edge: | The entire cutting surface of the knife, which extends from the point to the heel. The edge may be beveled or symmetric. |

| D | Heel: | The rear part of the blade, used for cutting activities that require more force |

| E | Spine: | The top, thicker portion of the blade, which adds weight and strength |

| F | Bolster: | The thick metal portion joining the handle and the blade, which adds weight and balance |

| G | Finger guard: | The portion of the bolster that keeps the cook's hand from slipping onto the blade |

| H | Choil: | The point where the heel meets the bolster |

| J | Tang: | The portion of the metal blade that extends into the handle, giving the knife stability and extra weight |

| K | Scales: | The two portions of handle material (wood, plastic, composite, etc.) that are attached to either side of the tang |

| L | Rivets: | The metal pins (usually 3) that hold the scales to the tang |

| M | Handle guard: | The lip below the butt of the handle, which gives the knife a better grip and prevents slipping |

| N | Butt: | The terminal end of the handle |

Material

- Carbon steel is an alloy of iron and carbon, often including other elements such as vanadium and manganese. Carbon steel commonly used in knives has around 1.0% carbon, is inexpensive, and holds its edge well. Carbon steel is normally easier to resharpen than many stainless steels, but is vulnerable to rust and stains. The blades should be cleaned, dried, and lubricated after each use. New carbon-steel knives may impart a metallic or "iron" flavour to acidic foods, though over time, the steel will acquire a patina of oxidation which will prevent corrosion. Unlike some grades of stainless steel good carbon steel will take a sharp edge but is not so hard as to be difficult to sharpen.

- Stainless steel is an alloy of iron, approximately 10–15% chromium, possibly nickel, and molybdenum, with only a small amount of carbon. Typical stainless steel knives are made of 420 stainless, a high-chromium stainless steel alloy often used in flatware. Stainless steel may be softer than carbon steel, but this makes it easier to sharpen. Stainless steel knives resist rust and corrosion better than carbon steel knives.

- High carbon stainless steel is a stainless steel alloy with a relatively high amount of carbon compared to other stainless alloys. The increased carbon content is intended to provide the best attributes of carbon steel and ordinary stainless steel. High carbon stainless steel blades do not discolour or stain, and maintain a sharp edge for a reasonable time. Most 'high-carbon' stainless blades are made of more expensive alloys than less-expensive stainless knives, often including amounts of molybdenum, vanadium, cobalt, and other components intended to increase strength, edge-holding, and cutting ability.

- Laminate blades combine the advantages of a hard, but brittle steel which will hold a good edge but is easily chipped and damaged, with a tougher steel less susceptible to damage and chipping, but incapable of taking a good edge. The hard steel is sandwiched (laminated) and protected between layers of the tougher steel. The hard steel forms the edge of the knife; it will take a more acute grind than a less hard steel, and will stay sharp longer.

- Titanium is lighter and more wear-resistant though not harder than steel but it is more flexible than steel. Titanium does not impart any flavour to food. It is typically expensive and not well suited to cutlery.

- Ceramic knife are very hard, made from sintered zirconium dioxide, and retain their sharp edge for a long time. They are light in weight, do not impart any taste to food and do not corrode. Suitable for slicing fruit, vegetables and boneless meat. Ceramic knives are best used as a specialist kitchen utensil. Recent manufacturing improvements have made them less brittle. Because of their hardness and brittle edges sharpening requires special techniques.

Knife Shapes

Prep Knives

- Chef's knife

Also known as a cook's knife or French knife, the chef's knife is an all-purpose knife that is curved to allow the cook to rock the knife on the cutting board for a more precise cut. The broad and heavy blade also serves for chopping bone instead of the cleaver, making this knife the all purpose heavy knife for food preparation. Chef's knives are most commonly available between 15 cm and 30 cm (6 and 12 inches), though 20 cm (8 inches) is the most common size.

- Paring

A paring knife is a small all-purpose knife with a plain edge that is ideal for peeling (or "paring") fruits and vegetables, and other small or intricate work (such as de-veining a shrimp, removing the seeds from a jalapeño, 'skinning' or cutting small garnishes). Paring knives are usually 6 to 10 cm (2½ to 4 inches) long. An alternative way to peel vegetables and fruit is to use a peeler. 16th century French bookbinders used a tool also known as a paring knife (couteau à parer) to thin the edges of the leather binding being prepared to cover a book in order to ensure it was neater and stuck better to the board. The knife was a large piece of steel, very thin at the cutting edge, with a wooden handle.

- Utility

In kitchen usage, a utility knife is between a chef's knife and paring knife in size, about 10 cm and 18 cm (4 and 7 inches) in length. The utility knife has declined in popularity, and is at times derided as filler for knife sets.[citation needed] This decline is attributed to the knife being neither fish nor fowl: compared to a chef's knife, it is too short for many food items, has insufficient clearance when used at a cutting board, and is too fragile for heavier cutting tasks, while compared to a paring knife, which is used when cutting between one's hands (e.g., carving a radish), the added length offers no benefit and indeed makes control harder in these fine tasks.[4] Some designs have a serrated blade. Outside of the kitchen, the term "utility knife" refers to a cutting tool with a short blade which can be replaced, or with a strip of blades which can be snapped off when worn. Further information: Utility knife

- Bread knife

Serrated knives are able to cut soft bread without crushing it; one was exhibited at the World's Columbian Exposition in 1893 in Chicago by the Friedrich Dick company (Esslingen, Germany).[5] One design was patented in the United States by Joseph E. Burns of Syracuse, New York.[6] His knife had sections of grooves or serrations, inclined with respect to the axis of the blade, that form individual small cutting edges which were perpendicular to the blade and thus cut without the excessive normal pressure required of a scalloped blade and without the horizontal force required by positive-raked teeth that would dig into the bread like a wood saw. There were also sections of grooves with the opposite direction of inclination, separated by a section of smooth blade, and the knife thus cut cleanly in both directions in both hard and soft bread. Bread knives are usually between 15 cm and 25 cm (6 and 10 inches). An offset bread knife 'doglegs' the handle above but parallel to the blade (rather than inline with it, although some are angled), providing clearance for the user's knuckles. This design makes it easier for the user to cut fully through the loaf without using an awkward grip, angling and 'see-sawing' the blade, or needing to position the knife handle over the edge of the counter or cutting board. While fairly specialized and unnecessary for most kitchens (and breads), the offset design is well-suited for high-volume/'production' work where much bread - particularly e.g. crusty loaves of baguette-type bread - is cut regularly and/or over long periods, to reduce fatigue. An alternative seen mostly in Europe is a baguette "chopper" or "guillotine" - not properly a knife, and prone to produce more of a "crushing" cut depending on the bread - but serving the same function.

- Butter knife

Butter knives have a dull cutting edge and are generally used for spreading. They are typically thought of more as servingware (used more as part of a table setting), to be used by diners to serve and/or spread butter or other soft spreadable foods, i.e. soft cheeses or jams, than as a kitchen or food preparation tool. A modern variant that is intended for food prep is the 'sandwich spreader' - a broad, flexible, almost spatula-like tool, with a rounded end and often with one serrated edge, similar to that used by pastry chefs to ice cakes. This is useful for spreading butter, mayonnaise/mustard, other similar 'spreads' or dressings, sandwich 'salad' toppings like egg salad, chicken salad, ham spread, etc., on bread.

Meat knives

- Carving

A carving knife is a large knife (between 20 cm and 38 cm (8 and 15 inches)) that is used to slice thin cuts of meat, including poultry, roasts, hams, and other large cooked meats. A carving knife is much thinner than a chef's knife (particularly at the spine), enabling it to carve thinner, more precise slices.

- Slicing

A slicing knife serves a similar function to a carving knife, although it is generally longer and narrower. Slicers may have plain or serrated edges. Such knives often incorporate blunted or rounded tips, and feature kullenschliff (Swedish/German: "hill-sharpened") or Granton edge (scalloped blades) to improve meat separation. Slicers are designed to precisely cut smaller and thinner slices of meat, and are normally more flexible to accomplish this task. As such, many cooks find them better suited to slicing ham, roasts, fish, or barbecued beef and pork and venison.

- Ham slicer

A ham slicer is a special type of slicer, with a long blade and rounded tip, that is offered by some manufacturers. The average size of the knife is between 9 and 15 inches. They are specially tailored to cutting ham, as they are generally thinner and more flexible. Another use can be for bigger fruit, like watermelon or cantaloupe.

- Cleaver

A meat cleaver is a large, most often rectangular knife that is used for splitting or "cleaving" meat and bone. A cleaver may be distinguished from a kitchen knife of similar shape by the fact that it has a heavy blade that is thick from the spine to quite near the edge. The edge is sharply beveled and the bevel is typically convex. The knife is designed to cut with a swift stroke without cracking, splintering or bending the blade. Many cleavers have a hole in the end to allow them to be easily hung on a rack. Cleavers are an essential tool for any restaurant that prepares its own meat. The cleaver most often found in a home knife set is a light-duty cleaver about 6 in (15 cm) long. Heavy cleavers with much thicker blades are often found in the trade. A "lobster splitter" is a light-duty cleaver used mainly for shellfish and fowl which has the profile of a chef's knife. The Chinese chef's knife is sometimes called a "Chinese cleaver", due to the rectangular blade, but it is unsuitable for cleaving, its thin blade instead designed for slicing; actual Chinese cleavers are heavier and similar to Western cleavers. A cleaver is most popularly known as butcher knife which is the commonly used by chefs for cutting big slices of meat and poultry.

- Boning

.jpg.webp)

A boning knife is used to remove bones from cuts of meat. It has a thin, flexible blade, usually about 12 cm to 15 cm (5 or 6 inches) long, that allows it to get in to small spaces. A stiff boning knife is good for beef and pork, and a flexible one is preferred for poultry and fish.

- Fillet

Fillet knives are like very flexible boning knives that are used to fillet and prepare fish. They have blades about 15 cm to 28 cm (6 to 11 inches) long, allowing them to move easily along the backbone and under the skin of fish.

Cheese knives

Cheese is varied and often challenging to cut. Accordingly, various styles of cheese knives and cheese cutting utensils have been developed. A wire, rather than a knife, is often used to cut cheese.

- Soft cheese

Soft cheese knives are specially designed for slicing soft cheese. They generally have holes in the blade to prevent the cheese from sticking. Wire cheese cutters are also used.

- Hard cheese

Hard cheese knives are specially designed for slicing hard cheese. They are sharp, so they can cut exact slices, and often have a forked tip, allowing them to be used as a serving utensil as well. Cheese slicers are also used.

- Parmesan cheese

A Parmesan cheese knife, featuring a short, stubby blade. Parmesan cheese knives are specially designed for portioning very hard cheeses. They have very short, thick blades that are forced into the cheese and then used as a lever to break off smaller portions. (Slicing hard cheese is considered improper by connoisseurs since the cheese - when broken apart - has more surface area, and thus more air contact, which strengthens the apparent scent and taste of the cheese.)

CARING FOR YOUR KNIFE

The blades should be cleaned, dried, and lubricated after each use.

Knife Sharpening

- Steel

Honing steels are used by lightly placing the near edge of the blade against the base of the steel, then sliding the blade away from yourself along the steel while moving it down – the blade moves diagonally, while the steel remains stationary. This should be done with the blade held at an angle to the steel, usually about 20°, and repeating on the opposite side at the same angle. This is repeated five to ten times per side.

It is often recommended that steeling be performed immediately before or after using a knife[2] and can be done daily. By contrast, knives are generally sharpened much less frequently. A traditional smooth honing steel is of no use if the edge is blunt, because it removes no material; instead it fixes deformations along the edge of a sharp blade, technically known as burnishing

- Sharpening Stone

Sharpening stones, water stones or whetstones are used to sharpen the edges of steel tools and implements through grinding and honing.

Sharpening stones come in a wide range of shapes, sizes, and material compositions. Stones may be flat, for working flat edges, or shaped for more complex edges, such as those associated with some wood carving or woodturning tools. They may be composed of natural quarried material, or from man-made material.

Stones are usually available in various grades, which refer to the grit size of the abrasive particles in the stone. Grit size is given as a number, which indicates the spatial density of the particles. A higher number denotes a higher density and therefore smaller particles, which leads to a finer finish of the surface of the polished object.

Using your Knife

Gripping your knife

Technique for the use of a chef's knife is an individual preference. For more precise control most cooks prefer to grip the blade itself with the thumb and the index finger grasping the blade just to the front of the finger guard and the middle finger placed just opposite on the handle side of the finger guard below the bolster. This is commonly referred to as a "pinch grip". Those without culinary training often grip the handle with all four fingers and the thumb gathered underneath.

For fine slicing, the handle is raised up and down while the tip remains in contact with the cutting board and the cut object is pushed under the blade.

Controlling your knife

Cutting with your knife

Slicing

- HORIZONTAL SLICING

Chopping

COARSE CHOPPING CHOPPING PARSLEY AND SIMILAR FOODS CHOPPING GARLIC

Cutting Sticks and Dicing

- Cutting Julienne and Batonnet

Julienne, allumette, or french cut, is a culinary knife cut in which the food item is cut into long thin strips, similar to matchsticks. Common items to be julienned are carrots for carrots julienne, celery for céléris remoulade, or potatoes for Julienne Fries.

Trimming the ends of the vegetable and the edges to make four straight sides makes it easier to produce a uniform cut. Trimmings can be used for stocks, soups, purees, etc. The measurement for julienne is 1–2 mm × 1–2 mm × 4–5 cm (0.04–0.08 in × 0.04–0.08 in × 1.6–2 in). Julienne usually applies to vegetables prepared in this way but it can also be applied to the preparation of meat or fish, especially in stir fry techniques. Once julienned, turning the subject 90 degrees and dicing finely will produce brunoise (3 mm × 3 mm × 3 mm).

Batonnet translated literally from French, batonnet means "little stick". The batonnet measures approximately 1⁄4 by 1⁄4 by 2–2 1⁄2 inches (0.6 cm × 0.6 cm × 5 cm–6 cm). It is also the starting point for the small dice.

- Cutting Burnoise and Small, Medium and Large Dice

Cuts with six even sides include:

*Large dice ("Carré" meaning "square" in French); sides measuring approximately 3⁄4 inch (20 mm).

*Medium dice (Parmentier); sides measuring approximately 1⁄2 inch (13 mm).

*Small dice (Macédoine); sides measuring approximately 1⁄4 inch (5 mm).

*Brunoise; sides measuring approximately 1⁄8 inch (3 mm)

*Fine brunoise; sides measuring approximately 1⁄16 inch (2 mm)

- Cutting Pausanne

**Paysanne; 1⁄2 by 1⁄2 by 1⁄8 inch (10 mm × 10 mm × 3 mm) **Lozenge; diamond shape, 1⁄2 by 1⁄2 by 1⁄8 inch (10 mm × 10 mm × 3 mm) **Fermière; cut lengthwise and then sliced to desired thickness, 1⁄8–1⁄2 inch (3–10 mm) **Rondelle; cut to desired thickness, 1⁄8–1⁄2 inch (3–10 mm) **Tourné; 2 inches (50 mm) long with seven faces usually with a bulge in the center portion **Mirepoix; 3⁄16–1⁄4 inch (5–7 mm) **Rough Cut; chopped more or less randomly resulting in all pieces in a variety of sizes and shapes

- Dicing an Onion

Mincing

Tourner

Parisiennes

Using a Mandoline

References

- Wikipedia article:Kitchen knife

- Wikipedia article:Honing steel

- Wikipedia article:Chef's knife

- Wikipedia article:Julienning

- Wikipedia article:List of culinary knife cuts

- Wikipedia article:Chef's knife